- Water treatment

- Water treatment

Mitsubishi-Eaton STRAIN-O-MATIC Strainers

- Water treatment

- Water treatment

Mitsubishi-Eaton STRAIN-O-MATIC Strainers

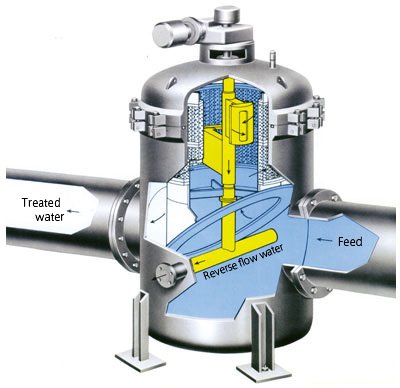

These innovative self-cleaning strainers automatically and efficiently remove solids from liquids in pipeline systems. The solids are all captured by a screen and discharged from the strainer by a powerful suction reverse flow or backwash system.

Features

- Powerful backwashing: The symmetrically balanced backwash arm is driven smoothly by a low output motor. The gap between the screen and port seal is kept very small to minimize the amount of solid matter bypassing the backwash flow, thereby maximizing the effectiveness of the backwashing using the minimum quantity of water.

- Corrugated screen with large surface area: The tapered shape of the screen lining ensures that solid matter is easily removed and discharged.

- Easy disassembly facilitates inspection and maintenance: The unitary design of the actuator and top cover gives simple access for inspection and maintenance.

- Large interior promotes separation and sedimentation of heavy solid matter: The ample space inside the strainer means that the feed flow decelerates and large solid matter separates and settles naturally at the bottom of the strainer.

- Low pressure loss flow: The flow suffers little turbulence or energy loss inside the strainer, keeping strainer pressure losses extremely small.

Lineups

| Model | Size | Throughput (㎥/min) |

|---|---|---|

| 596A | 2B | 0.72 |

| 3B | 1.16 | |

| 4B | 1.54 | |

| 6B | 4.44 | |

| 8B | 5.91 | |

| 10B | 9.68 | |

| 12B | 11.9 | |

| 14B | 17.6 | |

| 16B | 21.7 | |

| 20B | 30.3 | |

| 24B | 44.2 | |

| 30B | 69.8 | |

| 36B | 100 | |

| 44B | 149 | |

| 600A | 42B | 175 |

| 48B | 230 | |

| 60B | 370 | |

| 84B | 715 |

Note:

- Screen aperture ratio: 30%

- Initial pressure differential: 0.01 MPa (0.1 kgf/cm2)

Main Applications

- Electric power, petroleum industries : Seawater

- Gas industry : Seawater for LNG vaporizer

- Steel & paper industries : Industrial water

- Sewage works : Treated water

- Semiconductor industry : Caustic soda solution