Research and Development

Initiatives for Research and Development

In 2022, our company newly established the "Technology Development & Production Headquarters" that engages in cross-divisional activities of technological development and production and plays a central role in creating new products and businesses with the aim of realizing the "Mitsubishi Kakoki Group's Management Vision for 2050." We strive to foster company-wide values that cross the barriers between the segments and group companies, while creating a sense of unity regarding "technology development" and "manufacturing technology". As a basis for opening up new business areas, we will take the lead in further research into various elemental technologies and development of new technologies and products by making the most of the superior technologies that our company has developed for many years, a rich variety of our testing machines, and the agility of our personnel in charge.

Core technologies

Our company engages in development of new technologies and produces products based on the results of such development activities by combining the core technology of solid, liquid, and gas separation that our company has developed since foundation and a plethora of elemental technologies that we have created in each area of the Engineering Business (Plant Engineering Business, and Environment, Hydrogen, and Energy Business) and the Industrial Machinery Business.

Hydrogen energy-related technology

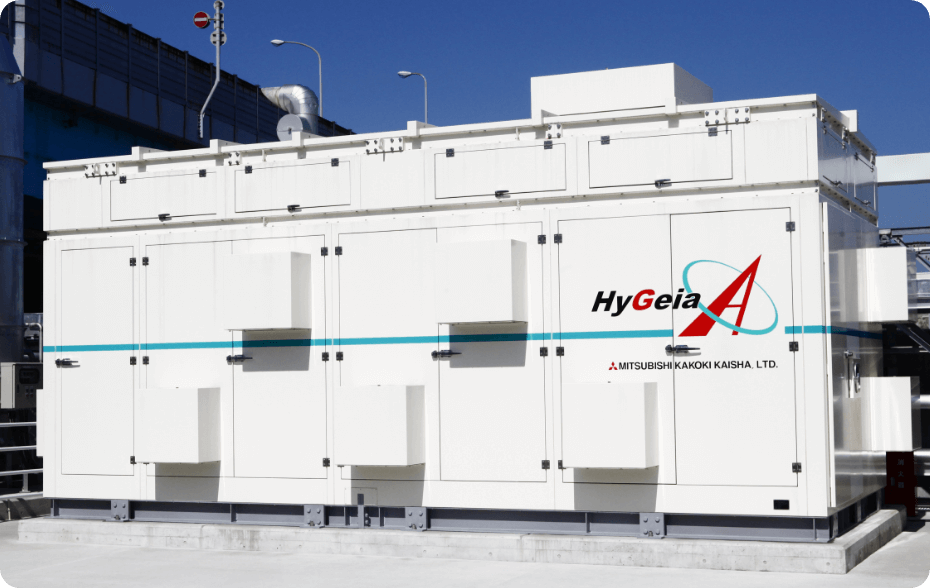

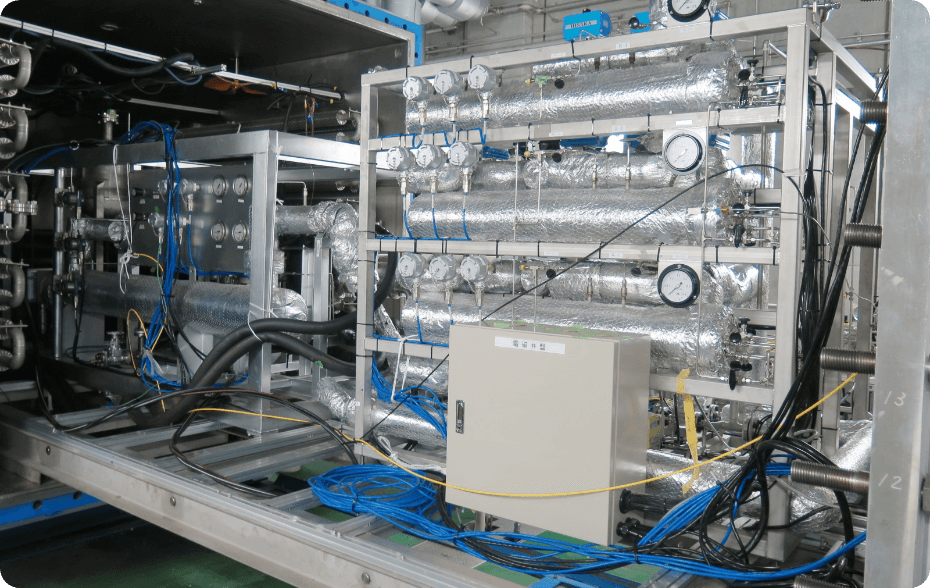

Hydrogen is drawing attention as a source of energy for creating a carbon-neutral society. Our company has been related to hydrogen for a long period of time and has acquired know-how about the production and effective use of hydrogen since we delivered our first hydrogen generator in 1964. We will endeavor to realize carbon neutrality by propelling forward research and development regarding hydrogen, which are our forte, including "HyGeia," the small-scale on-site hydrogen generator, the hydrogen absorbing alloy compressor, the water electrolysis-based hydrogen generator, and the technology of producing hydrogen from sewage biogas released from the digestion process at sewage treatment plants.

"HyGeia", the small-scale on-site hydrogen generator

Hydrogen station

Water electrolysis-based hydrogen generator

Hydrogen absorbing alloy compressor (demonstrator)

Development of technology for industrial use of microalgae

A photobioreactor is urban biomass production equipment for culturing microalgae at buildings and factories located in urban areas. Microalgae, which grow by absorbing CO2 through photosynthesis, are expected to be used in industries as a sustainable biomass source. Our company is carrying out a demonstration experiment of utilizing CO2 emitted during the production process by hydrogen generators in culturing microalgae so as to develop a carbon recycling technology model. Furthermore, we are developing multifarious machines by applying our separation and extraction technology in order to produce biofuel from cultured microalgae.

Urban photobioreactor for algae biomass production

(Left) Centrifugal technology

(Right) Extraction technology

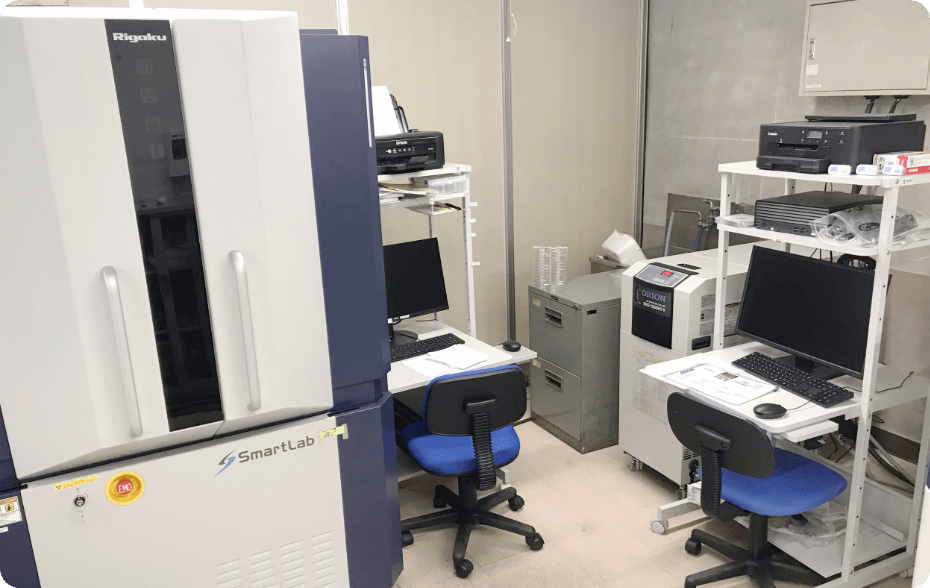

Application tests and research

Our company fulfills a multitude of needs from our customers by developing a wide range of fundamental technologies, such as applicability confirmation tests and analytical tests on various processes, with a primary focus given to the elemental technologies of each of our business segments. In the material technology area, we provide not only material testing, but also a service of damage analysis. We also offer equipment diagnosis for aged machines due to long-term use based on the know-how that we have acquired through these services, which is highly acclaimed by our customers.

Application tests

Applicability tests regarding technologies for separation and classification of various items including oily water and solid liquid

- Properties analysis and tests of subject samples

- Centrifuge testing

- Filtration and separation testing, etc.

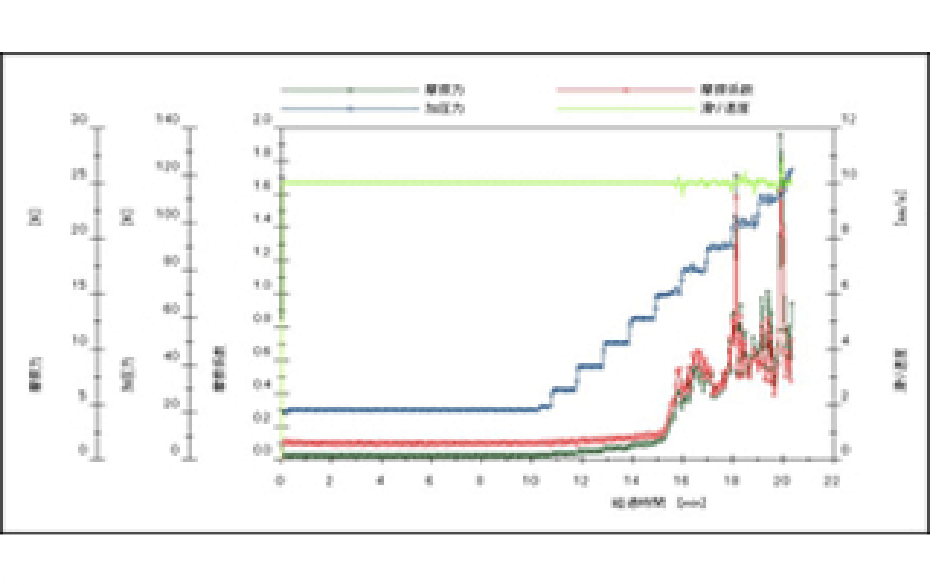

Material technology

Material testing and equipment diagnosis

Abrasion testing (abrasion coefficient measurement)

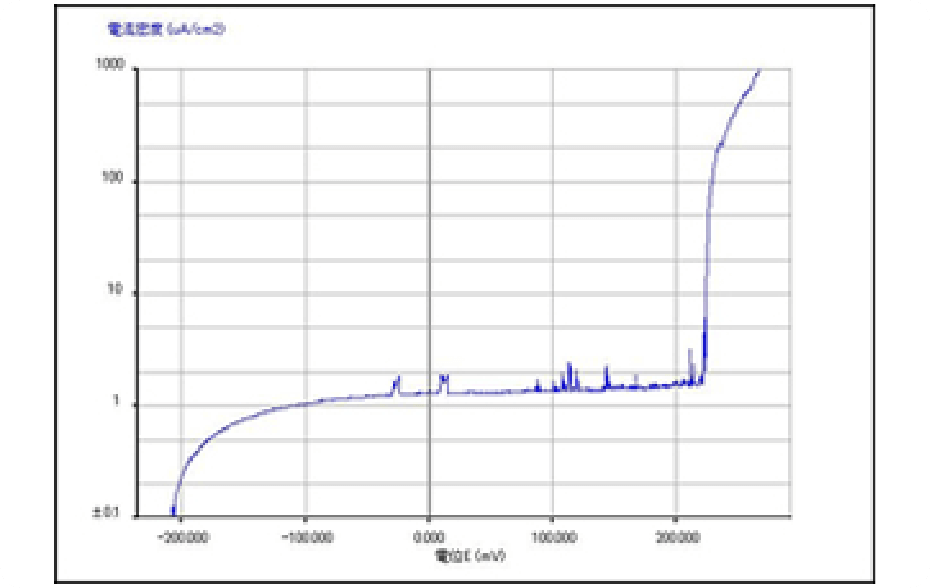

Corrosion testing (pitting potential measurement)

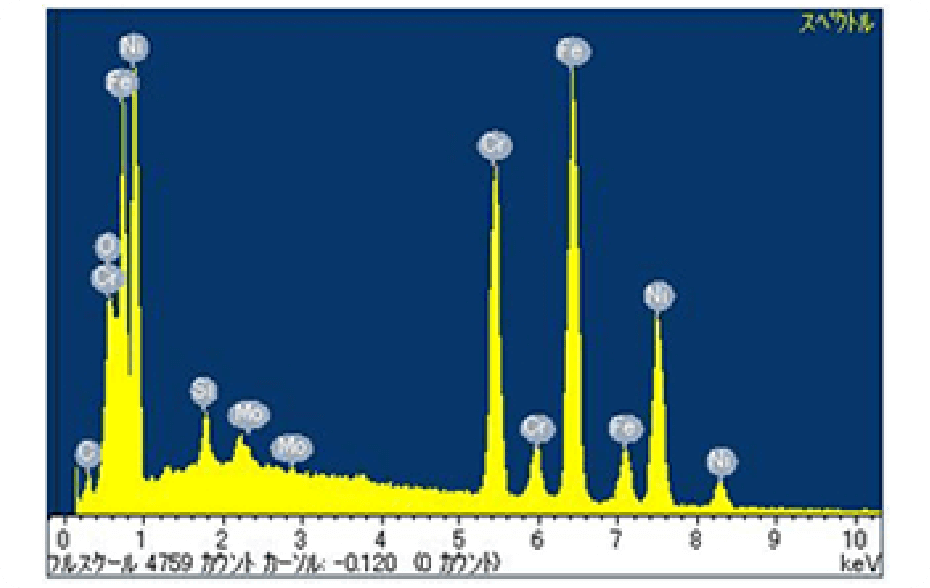

Chemical components analysis (qualitative and quantitative analyses)

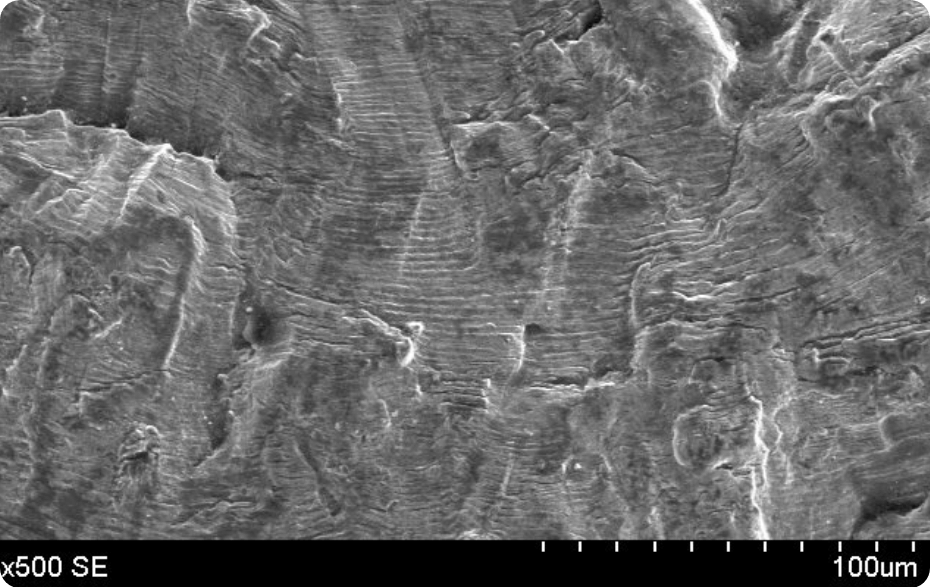

Fractography (metallic fatigue)

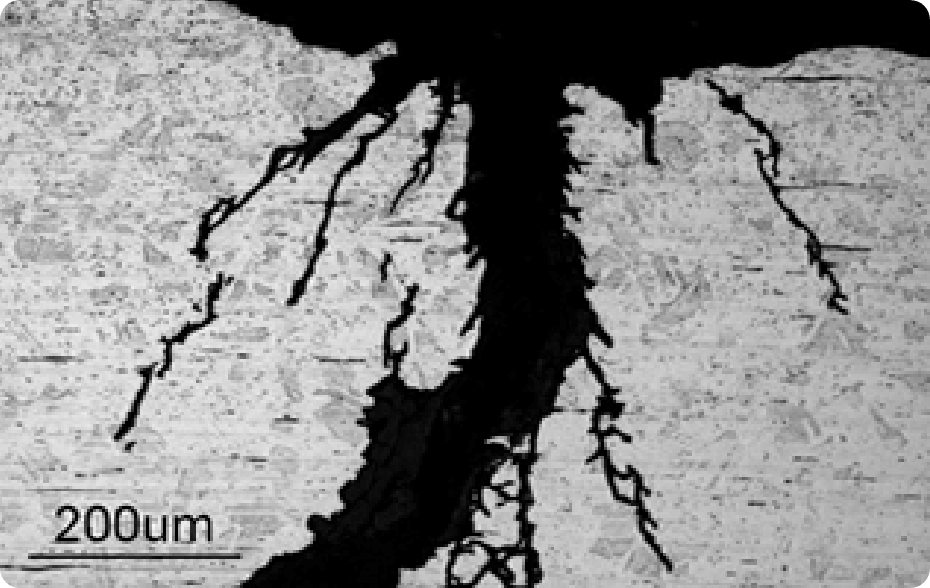

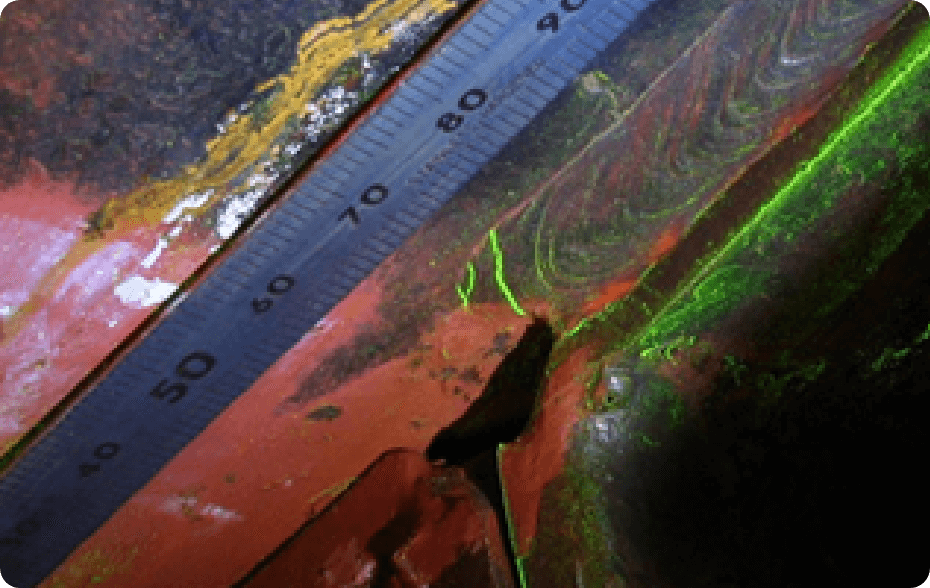

Microscopic observation (stress corrosion cracking)

Non-destructive inspection (magnetic particle testing)

Technological expansion

Our company strives to expand our technologies with an eye on new business and growth fields by developing new technologies and further pursuing the core technology.

Fields of technological expansion

- Green innovation

- Utilization of unused resources

- Fine chemistry

- Nanotechnology