Corporate History

-

1930 - 1959

-

-

1935

- Financed by the Mitsubishi Group Companies, Kakoki Seisaku, Ltd. (former company name) is founded to domestically manufacture machinery for the chemical industry.

- Receives first product order - for an autoclave (reactor).

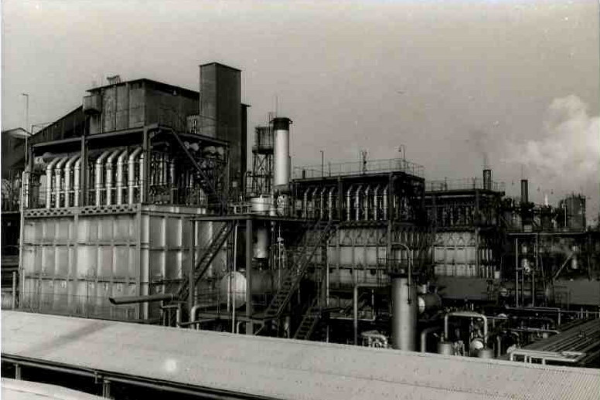

Photo 1 Kawasaki main plant at the time of its foundation

Photo 2 Yataro Iwasaki - the founder of Mitsubishi and the president of Mitsubishi Goshi Kaisha (limited partnership) visited Kawasaki main plant. (5th from right)

Photo 1

Photo 2

-

1936

- Receives first order for sulfuric acid generation plant.

-

1938

- Company name changed to Mitsubishi Kakoki Kaisha, Ltd. (MKK)

-

1940

- Develops Japan's first electrode baking furnace and takes first order.

- Receives first order for OP series oil purifier.

Photo The first OP series of oil pulifier

-

1941

- Delivers first air liquefaction separation plant.

-

1947

- Receives first order for penicillin generation plant.

- Orders from chemical companies for ammonia synthetic plant grow strongly.

-

1949

- Under Business Reconstruction and Adjustment Law, Mitsubishi Kakoki Kaisha, Ltd. (capitalized at \75 million) is reestablished as a secondary corporation to the former Mitsubishi Kakoki Kaisha, Ltd.

-

1950

- MKK is listed on the Tokyo and Osaka Stock exchanges.

-

1954

- Receives first order for carbureted water gas (CWG) plant, followed by strong growth in orders for city gas generation plants.

Photo CWG Plant

-

1957

- Delivers first Selfjector (SJ) oil purifier for ships.

-

1958

- Osaka Sales Office opens.

-

1959

- Receives first order for human waste digestion & sludge dewatering plant for sewage works, followed by strong growth in orders for water treatment plant.

Photo The first unit of the sewage sludge dewatering system for digesting human waste was delivered to the Sunamachi Sewage Treatment Plant in Tokyo.

-

-

1960 - 1989

-

-

1961

- Receives first order for sulfur recovery plant (Parsons type).

- Establishes Yokkaichi Factory (reorganized as Yokkaichi Works in 1973).

-

1963

- Receives first order for hydrogen generation plant.

Photo Hydrogen generation plant based on the ICI method for naphtha reforming (Toyosu Plant, Tokyo Gas Co.,Ltd.)

-

1964

- Receives first order from power generation company for bar screen filter.

-

1965

- Completes development of first activated sludge separator.

- Orders for industrial wastewater treatment facilities grow strongly.

-

1966

- Orders for centrifugal separators (decanter and peeler types) for industrial use grow strongly.

-

1970

- Kashima Factory commissioned.

- Cumulative production of SJ-OP series oil purifiers tops 10,000 units.

-

1971

- Completes first large-scale wet flue-gas desulfurization plant (employing Wellman Lord process)

-

1972

- Receives first order for SNG (Substitute Natural Gas) generator.

- Establishes Kakoki Kankyo Service, KK.

-

1977

- Splits off works division and establishes Kakoki Koji Kaisha, Ltd. (later renamed Kakoki E&C, KK. in 1990).

-

1978

- Receives order for large-scale electrode baking plant from Indonesia Asahan Aluminum.

- Completes first grey water treatment facility.

- Establishes Kakoki Trading Co., Ltd.

-

1983

- Develops supercritical gas extractor.

- Receives first order for LNG satellite station.

Photo Supercritical fluid extraction (SFE) facilities

-

1987

- Factory functions of Yokkaichi Works consolidated with Kawasaki Works and former is renamed Yokkaichi Office.

-

-

1990 - 2019

-

-

1991

- Delivers first UASB anaerobic wastewater reactor.

-

1992

- Osaka Sales Office is renamed Osaka Branch.

-

1994

- Develops CO2 membrane separation SNG generator.

Photo SNG generator

-

1995

- Relocates head office to 1-4-28 Mita, Minato-ku, Tokyo.

- Opens Project Center in Yokohama.

- Establishes MKK Europe B.V. in Amsterdam, The Netherlands through joint capital investment with Mitsubishi Corporation.

-

1996

- Osaka Branch is renamed Osaka Branch Office.

- Receives first order for permeable brick production plant using sewage sludge as raw material.

- Participates in Japanese Ministry of Health and Welfare's Eco-Land Plan (Sludge Recycling Treatment Center).

-

1997

- Head office functions relocated from Mita, Minato-ku, Tokyo to the Kawasaki Works in Kawasaki-ku, Kawasaki City, Kanagawa Prefecture.

(Head office relocated to 2-1 Ohkawa-cho, Kawasaki-ku, Kawasaki City in August 1998.)

- Head office functions relocated from Mita, Minato-ku, Tokyo to the Kawasaki Works in Kawasaki-ku, Kawasaki City, Kanagawa Prefecture.

-

1998

- Winds up Kakoki E&C, KK and establishes Kakoki Engineering, KK.

- Starts sales of horizontal centrifugal separators using Krauss-Maffei GmbH (Germany) technology and conforming to GMP production and quality standards for pharmaceuticals.

Photo HZ-ph, horizontal centrifugal separators conforming to GMP

-

1999

- Subsidiaries reorganization : Three technological companies were integrated into Kakoki Plant & Environment Engineering Co., Ltd. and two service companies into Kakoki Trading Co., Ltd.

- Develops and starts deliveries of small-scale onsite hydrogen generator producing 99.999% purity hydrogen.

- Cumulative sales of OP and SJ series oil purifiers top over 60,000 units.

-

2000

- Starts sales of new, compact SJ-UNIT series oil purifier.

-

2001

- Receives first order for waste gas abatement system for semiconductor industry.

- Establishes Head Sales Office in Miyamae-cho, Kawasaki-ku, Kawasaki City.

- Closes down Yokohama Project Center.

-

2002

- Starts sales of new SJ-GENIUS series marine oil purifiers.

Photo Mitsubishi oil purifier SJ-G series

-

2003

- Delivers first hydrogen station for fuel-cell vehicles.

-

2004

- Yokkaichi Office is renamed Yokkaichi Factory.

- Establishes Shanghai Representative Office (closed down in 2012).

-

2005

- Develops "HyGeia" new hydrogen generator.

- Introduces technology of ceramic sound absorption boards.

Photo The first model of HyGeia, new hydrogen generator

-

2006

- Develops MegaFuelTM bio-fuel production system which uses sewage sludge as feed material.

- Introduces Mitsubishi-VOS Ballast Water Management System using technology from NEI Treatment Systems LLC, USA.

-

2007

- Orders for hydrogen generators top 100 units since first order in 1963.

- Establishes Thailand Representative Office (closed down in 2012).

-

2008

- Establishes Ryoka Trading (Shanghai) Co., Ltd. wholly owned by MKK.

-

2009

- Completes second fabrication shop in Kashima factory.

-

2010

- Introduces executive officer system.

- Establishes MKK Asia Co., Ltd. in Bangkok, Thailand, in order to expand operations throughout the Southeast Asia region (MKK owns a 49% equity stake).

-

2011

- Cumulative production of Mitsubishi Selfjector oil purifiers tops 90,000 units.

-

2012

- Starts operation of new SJ (Oil Purifier) factory at Kawasaki Works.

- Launch of new Mitsubishi SJ HERCULES series.

Photo The SJ factory and SJ-H series

-

2013

- The next generation, high-efficiency model of hydrogen generator, HyGeia-A was developed and launched.

Photo High-efficiency model of hydrogen generator, HyGeia-A

-

2014

- Mitsubishi SOx Scrubber System, Japan's first system compatible with the regulations governing SOx emissions in ship exhaust gases, jointly developed with Mitsubishi Heavy Industries, Ltd.

-

2015

- Small scale on-site hydrogen generator "HyGeia Series" receives Low CO2 Kawasaki Brand Certification and Grand Prize and Kawasaki Mechanism Certification.

- "Demonstration of hydrogen generation from sewage biogas source" was selected for the Breakthrough by Dynamic Approach in Sewage High Technology (B-DASH) Project as a commissioned research project by the Ministry of Land, Infrastructure, Transport and Tourism.

Photo A hydrogen station using sewage bio gas.

-

2016

- Cumulative production of Mitsubishi self-injectors reaches 100,000 units.

- Transition to a company with an audit committee.

-

2017

- Hydrogen station for demonstration on a commercial scale, constructed in Kawasaki Works.

-

2018

- Established "Kawasaki Front Office" as a new base for the Plant Engineering Business and the Industrial Machinery Business at 580 Horikawa-cho, Saiwai-ku, Kawasaki-shi, Kanagawa Prefecture.

-

2019

Conducted the following organizational restructuring measures for the purposes of stabilizing the revenues of the entire corporate group and strengthening the earning capacity.

- The business of selling our oil purifiers of Ryoka Seisakusho Co., Ltd. was split off and absorbed by our company.

- Kakoki Plant & Environment Engineering Co., Ltd. absorbed Ryoka Seisakusho Co., Ltd.

(The company name after the merger was Kakoki Plant & Environment Engineering Co., Ltd., and was renamed to Mitsubishi Kakoki Advance, Ltd. in November 2020.) - The after-sales service business, which is part of the construction and plant engineering businesses of Yokkaichi and Kashima Factories of our company, was split off and absorbed by Kakoki Plant & Environment Engineering Co., Ltd.

-

-

2020 - Current

-

-

2020

- Kakoki Plant & Environment Engineering Co., Ltd. was renamed Mitsubishi Kakoki Advance, Ltd.

-

2021

- Established Taiwan Branch in Taipei City, Taiwan.

- Established our head office at 580 Horikawa-cho, Saiwai-ku, Kawasaki-shi, Kanagawa Prefecture, and transferred the headquarters functions from Kawasaki Works to the head office.

- Closed the marketing section of the head office and Kawasaki Front Office, and transferred each section to Kawasaki Works and the head office.

-

2022

- Transferred from the first section to the Prime Market of Tokyo Stock Exchange, through the market reclassification.

-

2023

- Endorsed "Kanagawa 50-Year Scheme for Forest Restoration" set by Kanagawa Prefecture

- Renewal of Yokkaichi Business Office

- Launched "mini CURUPO", a bench-scale rotary filtration machine

- Announcement of the world-first electric field filtration technology "Ele-Fil™"

Photo Yokkaichi Business Office

-

2024

- Announcement of the acquisition of shares in Tohsoh Corporation (Renaming to "MKK TOHOKU Corporation" in 2025)

- Announcement of the restructuring of the Head Office and Kawasaki Works

- Signed an official sponsorship agreement with Kawasaki Brave Thunders

Photo Overall layout plan that includes existing equipment, etc. (Image)

-