SNG (Substitute Natural Gas) Generation Plant

SNG (Substitute Natural Gas) Generation Plant

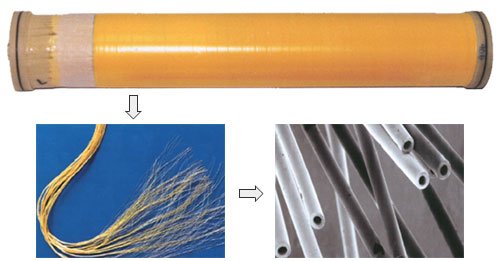

SNG (Substitute Natural Gas) generation plants produce high-calorific value city gas (45MJ/Nm3) by reforming of LPG (Liquefied Petroleum Gas), naphtha and COG (Coke Oven Gas). Unlike conventional wet absorption systems, the use of membrane separation technology in the CO2 removal process makes MKK SNG generators compact with low running costs and easy-to-operate.

Features

- Uses the CRG (Catalytic Rich Gas) low temperature reforming process widely proven in Japan and overseas.

- Very high thermal efficiency.

- Runs on a variety of feedstock, including naphtha, LPG and COG.

- Adiabatic reactor is of simple construction and easy to maintain.

- Uses long-lasting and high reliability reforming catalyst .

- Compact configuration.

- Low noise output.

- Requires no dehydrating unit.

Process Flow

Main Applications

- City Gas generation