- Energy

- Chemical

- Medicine

- Food

- Semiconductors/electronic materials

- Water treatment

- Centrifuge

- Precise separation and extraction

- Recycling

- Water treatment

Mitsubishi Disc Separator: SJ Series for Industrial Application

- Energy

- Chemical

- Medicine

- Food

- Semiconductors/electronic materials

- Water treatment

- Centrifuge

- Precise separation and extraction

- Recycling

- Water treatment

Mitsubishi Disc Separator: SJ Series for Industrial Application

Mitsubishi Disc Separator is a centrifugal separator which can separate solid matter from two kinds of different density liquids on a continuous basis and also to separate two liquids simultaneously. By reducing process cycle time and labor requirements, these separators offer high cost efficiency in liquid clarification and reclamation, solid-liquid separation and its classification, recovery and thickening of solids and in other such processes.

Features

- Centrifugal separation requiring no filter media.

- High reliability drive train system backed by delivery of over 2,000 units a year.

- Bowl design with superior separation performance and with good response to discharge loads.

- Pilot valve regulates total/partial discharge of solids.

- Vibration-proof design realizes long working life.

- Full automation possible with PLC automatic control panel.

Lineups

| Model |

Throughput (L/hr) |

Rotor speed (rpm) |

Motor output (kW) |

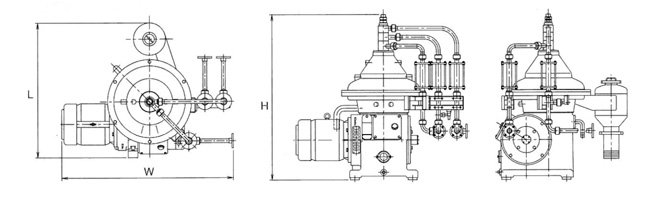

External dimensions L x W x H (mm) |

Weight (kg) |

|---|---|---|---|---|---|

| SJ10F | 1,600 | 9,000 | 5.5 | 1,000 x 910 x 1,025 | 365 |

| SJ30F | 4,600 | 9,000 | 5.5 | 1,013 x 920 x 1,045 | 380 |

| SJ40F | 7,000 | 7,300 | 7.5 | 1,188 x 1,092 x 1,231 | 780 |

| SJ80F | 12,000 | 5,600 | 15.0 | 1,426 x 1,195 x 1,386 | 1,150 |

| SJ120F | 20,000 | 4,500 | 22.0 | 1,450 x 1,810x 1,900 | 1,650 |

Main Applications

Chemical industry

- Classification of carbon, bentonite, calcium carbonate

- Solid-liquid separation of calcium oxide, aluminum hydroxide

- Liquid-liquid separation of water and solvents, different solvents, oils /fats and water

- Thickening of metal residue, pigments, resins.

Food processing and pharmaceutical industries

- Deacidification , degumming, rinsing process of vegetable oils and fats

- Recovery of oils, fats and proteins from animal fats

- Clarification of fruit juices, wine and other drinks

- Cell separation, yeast recovery.

Environmental conservation

- Separation and purification for SAF production and biofuels

- Oil-water separation and solid matter removal in oil and water-based coolants

- Purification of effluent and waste oil in various industry.

Oil purification

- Removal of contaminants from generator fuel and lubricating oil

- Removal of contaminants from quenching oil, cutting fluids and other working fluids.