- Energy

- Chemical

- Mixing

Mitsubishi Side Entering Mixer (SEM)

- Energy

- Chemical

- Mixing

Mitsubishi Side Entering Mixer (SEM)

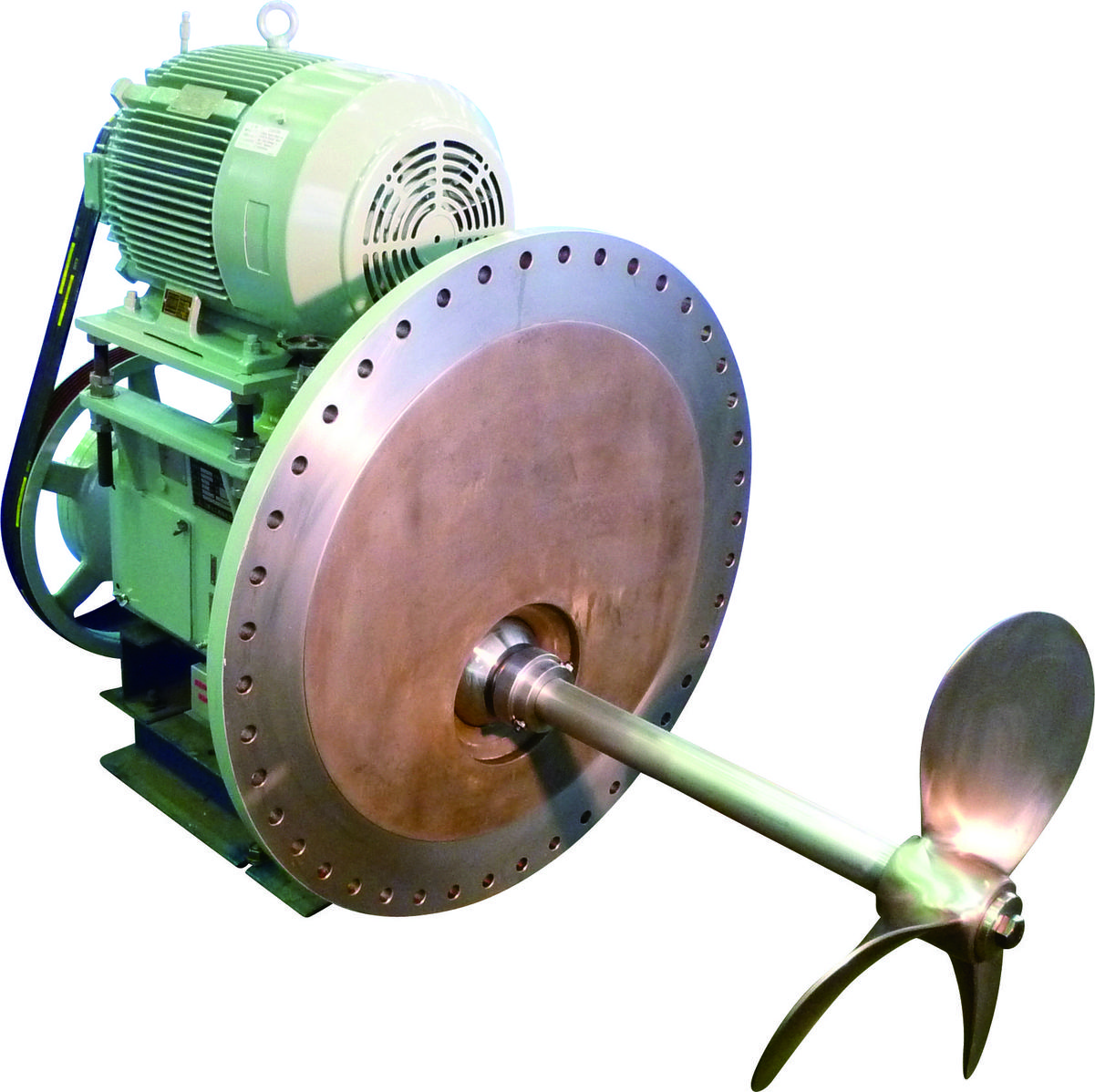

The side entering mixer (SEM), which has been sold more than 5,500 in Japan and abroad, comprises a motor, reduction gear and propeller. The Mitsubishi SEM line is available with a choice from three basic Model, Type 3, Type 4 and Type 5, each using a high mixing performance marine propeller. In each model there is a choice between gear and belt drive and between a fixed and swivel angle propeller, allowing the customer to choose the best suited configuration for the purpose. Mitsubishi SEMs are ideal for a wide range of delicate mixing applications.

Features

- Mitsubishi SEMs use a solid cast marine propeller.

- The mechanical seal is fitted close to the liquid in the tank to correspond to high viscosity fluids.

- Roller bearing allows operation over long periods of time.

- Pressure parts are made to a strong and durable design.

- The mechanical seal and bearing case use a unitary construction which makes for easier maintenance.

- The mixer mounting flange thickness conforms to API and JIS standards and is welded to the opening with full penetration welds.

- The spherical unit part uses double oil seals with special lip to prevent leakage of fluids.

- The hinge pin supporting the mixer is fixed by grooved nut and split pin to prevent loosening by abrasion or vibration.

- Gear drive mixers use precision machined gears for a quiet operation.

- Belt drive mixers offer the following features over gear drive models:

- Quieter operation

- Maintenance of all parts is possible without having to remove the motor.

- Requiring no gear oil, running costs are lower.

- The shut-off mechanism allows the mechanical seal and other consumable parts to be replaced while the tank is full of liquid.

Structural Drawing

Easily mounted to the manhole in the tank shell.

Main Applications

- Mitsubishi SEM is used to prevent oil sludge settling in crude oil tanks or storage tanks, to equalize properties and temperature, and to mix and dissolve dissimilar liquids. It can be also used for biofuel applications.

- Based on the solid track record listed above, it is also delivered for use in product tanks for solutions, etc.

- Please contact us about its application to SAF (Sustainable Aviation Fuel), which is expected as a measure of reducing CO2 emissions toward achieving carbon neutrality.