- Environmental improvement

- Ships

- Water treatment

Mitsubishi VOS Ballast Water Treatment System

- Environmental improvement

- Ships

- Water treatment

Mitsubishi VOS Ballast Water Treatment System

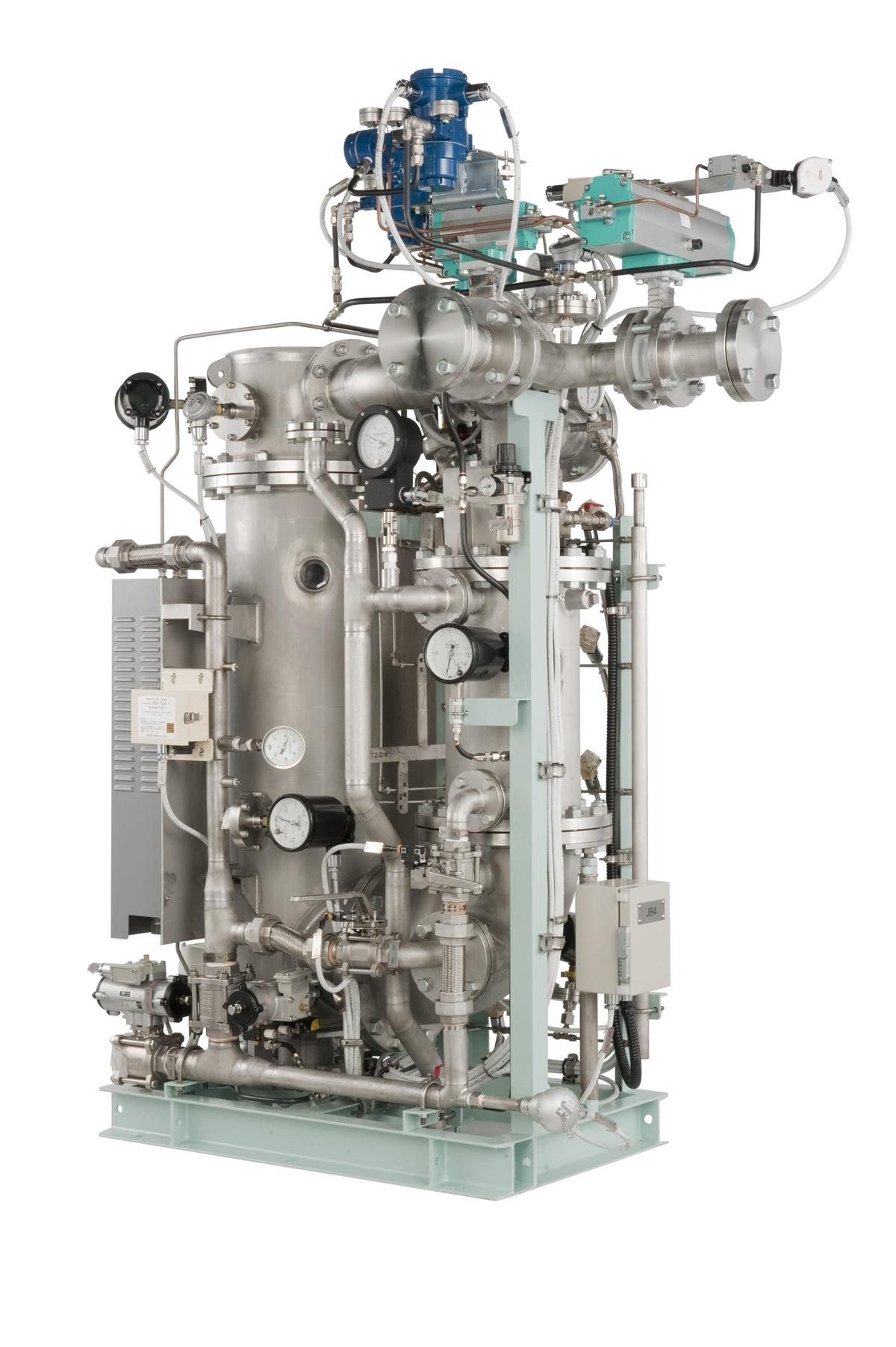

The Mitsubishi VOS*1 ballast water treatment system is the first of its kind to be certified as meeting the Regulation D-2 Ballast Water Performance Standard under the IMO*2 International Convention for the Control and Management of Ships' Ballast Water and Sediments.

VOS Systems are installed in many vessels ranging in size from general cargo vessels with a system throughput of 150 ㎥/hr to super tankers (VLCC) with a throughput of 6,800 ㎥/hr.

The main components of the system are widely used in the shipping industry and the system also serves to protect deterioration of ballast tank paint and reduce wear of sacrificial or galvanic anodes.

Note 1: Venturi Oxygen StrippingTM

Note 2: International Maritime Organization

Features

- Functions as a ballast tank anti-corrosion system without affecting the paint coating.

- The system has been installed in VLCC super tankers.

- The system can be readily adapted to explosion-proof specifications and only intrinsically safety component is installed in explosion-proof areas.

- Adopts existing proven IGG (Inert Gas Generation) technology.

- The system is equally effective for ships operating in freshwater, brackish water and seawater.

- The system uses no chemicals and only requires fuel to operate.

- World-wide service network is available to support the VOS System same as our SJ Series oil purifiers installed in the ships.

Specifications

- Standard throughput : 150 m3/hr to 6,800 m3/hr

- Certified by five countries:Republic of Liberia

Republic of the Marshall Islands

Republic of Malta

Republic of Panama

The Netherlands.

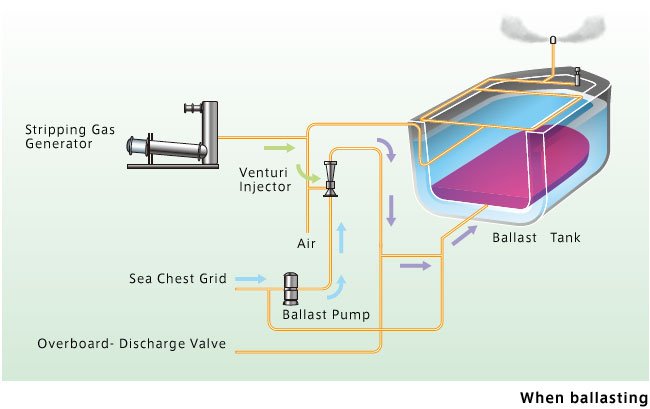

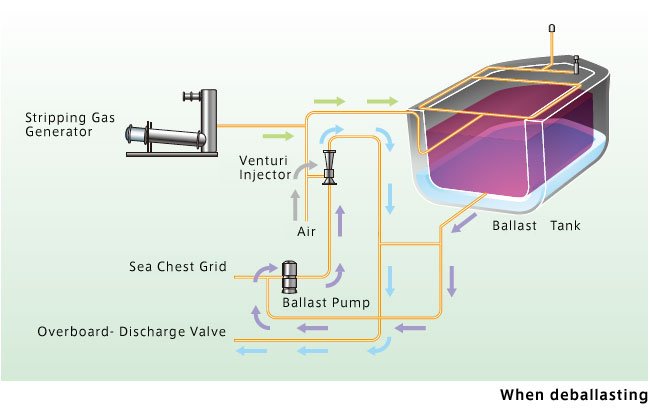

Flow Chart

Main Applications

- Ship ballast water treatment

Lineup

| Model | Type250 | Type500 | Type1000 | Type2000 | Type3000 | Type4000 | Type6000 |

|---|---|---|---|---|---|---|---|

| Throughput (㎥/hr) | 150-300 | 850 | 1,300 | 2,400 | 3,600 | 5,200 | 6,800 |