Engineering Business

The engineering business of our corporate group has grown along with the industrial development of Japan. Our expansion into overseas markets dates back over 70 years. Since then, we have developed diverse businesses, from lifelines such as city gas, hydrogen, water, and sewage systems to chemical plants for semiconductor materials/petrochemicals and pharmaceutical production facilities. In recent years, we have been engaged in the world's first project to produce hydrogen from biogas derived from sewage and operating hydrogen stations.

Plant Engineering Business

Proactively developing business as a pioneering manufacturer of machinery for the chemical industry. As a comprehensive engineering company involved in all processes from the manufacturing of plant equipment to proposal of plans, design, procurement, and construction, our company is developing its business with a focus on the EPC business*.

*An acronym for Engineering, Procurement, and Construction.

Main Business

General chemical plants, pharmaceutical plants, food processing plants, etc.

Forte

- EPC know-how in various areas accumulated since the 1950s

- Extensive overseas experience, particularly in Southeast Asia

- Comprehensive O&M * know-how that extends beyond the delivery of equipment and facilities to maintenance and other services

*Operation & Maintenance

Environment, Hydrogen, and Energy Business

Our company's business is centered on the construction of energy-related equipment and facilities for city gas, petroleum, hydrogen, and sulfur recovery. We have technological capabilities in areas that are attracting attention as next-generation clean energy, such as the "HyGeia," a series of on-site hydrogen generator.

Since the late 1950s, our company has been engaged in environmental improvement projects such as water pollution control. In recent years, it has developed its business around the construction of sewage, industrial waste, and other treatment facilities.

Main Business

Various water treatment facilities, waste treatment facilities, deodorization equipment, city gas-related plants, hydrogen generators, biogas plants, etc.

Forte

- Technology related to gas production and refining since its establishment

- EPC know-how in various areas accumulated since the 1950s

- Comprehensive O&M * know-how that extends beyond the delivery of equipment and facilities to maintenance and other services

*Operation & Maintenance

Key Initiatives

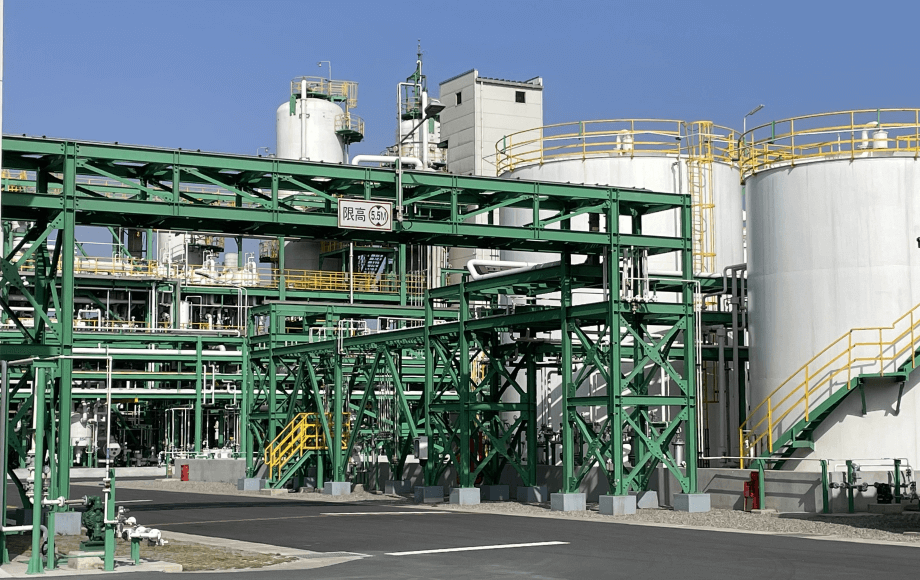

"Hydrogen peroxide production facility" designed, procured, and constructed for MGC Pure Chemicals Taiwan, Inc.

Contributing to the strengthening of the semiconductor supply chain by constructing a hydrogen peroxide production facility

In June 2023, our company completed construction of a hydrogen peroxide production facility, which was planned by Mitsubishi Gas Chemical Company, Inc's subsidiary, MGC Pure Chemicals Taiwan, Inc., and for which it received an integrated order from design to construction (EPC).

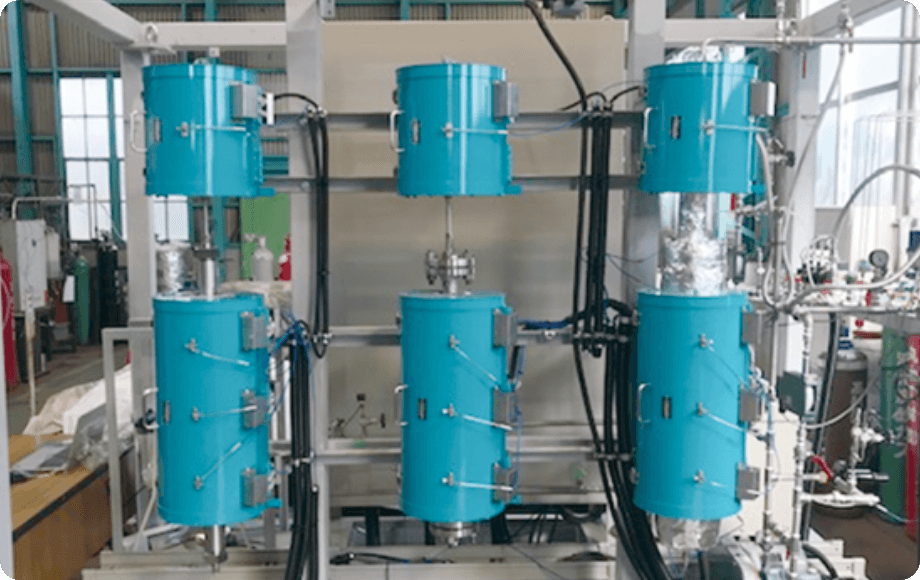

The "gas reform demonstration test facility" for the gas reforming process, which is the scope for our company's demonstration.

Endeavoring to develop a resources recycling system for "miscellaneous waste plastics" through chemical recycling

As marine plastics have become a social issue, there is a rapidly growing need to develop recycling methods for the miscellaneous waste plastics incinerated or landfilled due to their low purity and cleanliness.

Our company is engaged in this demonstration project for constructing a reforming process of synthesis gas obtained from waste plastics, thus contributing to resolving the plastics problem.

Medium-sized machine "M-HyGeia" to be delivered to Toho Gas Co., Ltd.

Promoting the realization of a hydrogen and carbon neutral society through participation in the hydrogen supply chain, etc .

As initiatives to increase the use of hydrogen for carbon neutrality are emerging everywhere, our company is expanding its sales activities for the decarbonization of various industries by utilizing the "HyGeia" series of on-site hydrogen generators, which hold the largest share in the market.

Delivered "thermal sludge solubilizer"

Simultaneously reducing sewage sludge disposal costs, increasing biogas revenues, and reducing energy consumption in the sewage sludge treatment process.

The first unit of the thermal sludge solubilizer ordered by Karatsu City was completed at the Karatsu City water purification center. This technology was developed jointly with Japan Sewage Works Agency. In 2017, a project including this technology was adopted by the Ministry of Land, Infrastructure, Transport and Tourism for a demonstration project with a joint research team of Karatsu City, Kyushu University, Japan Sewage Works Agency, and Mitsubishi Kakoki Kaisha, Ltd., conducted a demonstration project at this purification center and issued guidelines for technology introduction in 2019.