Industrial Machinery Business

Our corporate group was created with the objective of domestically manufacturing machinery for the chemical industry, and the industrial machinery business is the history of our company itself. Our company has developed and manufactured many centrifuges and filtration machines using its core technologies for separation and filtration, including an oil purifier, which was developed in the 1930s and still a mainstream product.

In recent years, our company has focused in the areas of nanotechnology and microfiltration, and as an "industry that supports industry," it aims to further innovate things by utilizing the technologies it has cultivated so far.

Business Details

Based on the "solid-liquid separation technology" we have developed since our founding, we develop, design, manufacture, and sell a wide variety of industrial machinery such as filters, centrifuges, and dust collectors. We provide customers with complete support, including the selection of an optimum model, the delivery of the equipment, and after-sales services.

We are also working to improve existing machines and develop new products to meet customers' requests and needs.

Major Businesses

Oil purifiers, centrifuges, filtration equipment, dust removal equipment, agitators, dryers, equipment for environmental regulations for ships, etc.

Strengths

- Manufacturing based on "solid-liquid separation technology" cultivated since the company's founding, including oil purifiers

- Integrated customer support including not only the delivery of equipment and facilities, but also maintenance

- Marine equipment mounting technology developed over 80 years

Main Initiatives and Achievements

Mitsubishi Selfjector, Mitsubishi's oil purifiers that have held the largest market share for many years (Photo: SJ-H series)

"Mitsubishi Oil Purifiers," which have held the largest market share for many years, are making steady progress in supporting new fuel vessels that contribute to carbon neutrality.

We are cooperating with National Maritime Research Institute in their onboard testing of biodiesel fuel for use on ships by providing our Mitsubishi Selfjector, an oil purifier that boasts the largest market share.

Through this cooperation in tests, we will establish methods for applying oil purifiers when using biodiesel fuel in marine vessels.

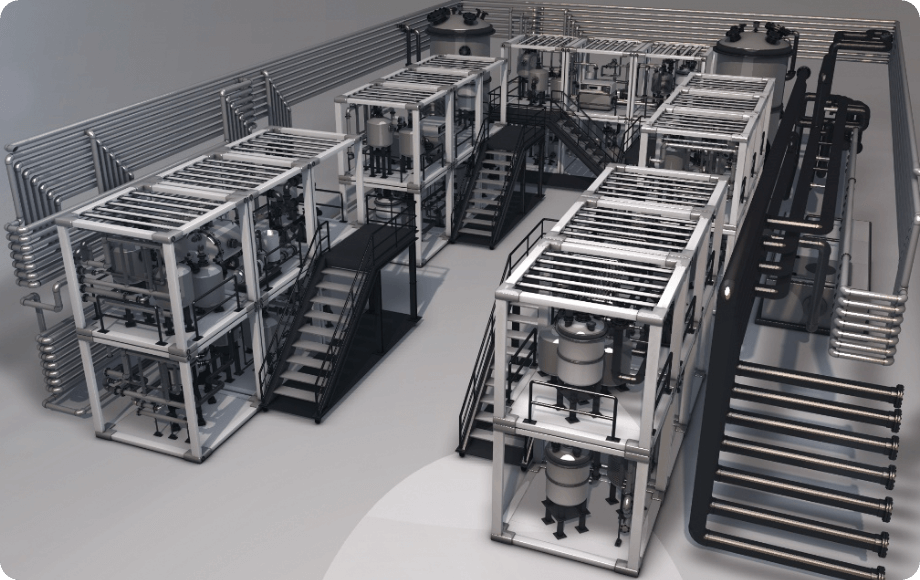

iFactory®, a modular automated continuous production facility that revolutionizes the manufacturing of functional chemicals (Photo: courtesy of iFactory Inc.)

The modular filtration and drying machine we have developed solve the problems with the pharmaceutical industry by realizing "on-demand production."

"iFactory®," which was jointly developed through a demonstration project in which we participated, is a modular pharmaceutical and functional chemical manufacturing facility that enables on-demand production of pharmaceuticals for greater efficiency and a significant reduction in the associated carbon footprint.

The greatest feature of this facility is that it can reconfigure the production line by changing the type and arrangement of modules in response to changes in raw materials or production items, and produce the required products in the required quantities (on-demand production).

Wastewater treatment equipment for EGR engine systems

In anticipation of the adoption of next-generation fuel for ships, we are taking the lead in developing exhaust gas purification systems for ship engines.

We manufacture and sell wastewater treatment equipment for EGR engine systems that reduce NOx emissions from ships.

In consideration of environmental regulations, methanol-fueled EGR engines and "EcoEGR" fuel engines with improved fuel efficiency are being developed and introduced to the market one after another. We have launched a model of wastewater treatment equipment suitable for the above-mentioned engines and are developing it as part of our product lineup.

Mitsubishi Dyna Filter

Precise separation of nano-sized fine particle slurry. Proposes new value creation for various industries such as chemical, pharmaceutical, metal, and food.

The Mitsubishi Dyna Filter can precisely separate nano-sized fine particle slurry and recover highly concentrated liquid and clarified filtrate, and can be used in a variety of applications, in a lineup ranging from small machines for R&D to large machines for mass production, to meet diverse needs by incorporating it into the manufacturing process of various products.

Our centrifuge "Mitsubishi Disc Separator"

It has been decided that the Mitsubishi Disc Separator for refining waste cooking oil will be used for Japan's first large-scale demonstration facility for producing domestic SAF.

Separator SJ Series, a separator plate type centrifugal separator, for the construction of Japan's first large-scale production demonstration facility of SAF (Sustainable Aviation Fuel), which is domestically produced from waste cooking oil. Our disc separators have been highly evaluated for their separation performance and will be used to remove foreign substances from raw waste edible oil.

Nutche Filter Type Extractor

Supplying Nutsche filter-type extraction equipment for SAF extraction from algae

This system was supplied to New Energy and Industrial Technology Development Organization (NEDO) for technological development of the extraction process in the re-commissioned research for the "Development of Production Technologies for Biojet Fuels."

Major Manufacturing Plants

SJ Plant of Kawasaki Works

- Oil Purifier: Kawasaki Works

- Wastewater Treatment Equipment for EGR Engine Systems: Kawasaki Works

- Centrifuges, Filters, Agitators: Kawasaki Works

Second Can Manufacturing Plant of Kashima Factory

- Dust collector: Kashima Factory

- Pressure vessels: KashimaFactory, Mitsubishi Kakoki Advance Co., Ltd. Kitakyushu Factory