- Energy

- Water treatment

- Water treatment

Mitsubishi Screen Equipment

- Energy

- Water treatment

- Water treatment

Mitsubishi Screen Equipment

Screen Equipment is an essential equipment because thermal and nuclear power stations located by the sea or the river use huge amounts of seawater or river water as cooling water.

Mitsubishi screen equipment is used to remove seaweed, fish, jellyfish, rubbish and other refuse from the water.

MKK keeps trying to realize more reliable and responsible equipment for the needs of users throughout the world.

Features

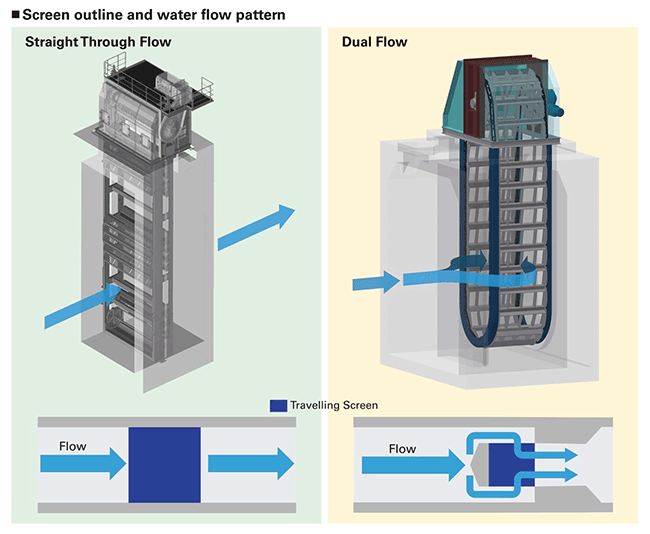

Travelling screen

This type of screen is important equipment which arrests and removes smaller debris to protect downstream equipment from being clogging. Travelling screen is better to remove debris, like as jellyfish, from water intake pit area than Bar screen with trash rake in the upper flow. Travelling screens are mainly classified into two types, Straight Through type and Dual Flow type.

Straight Through Type

- Simple, large screening area baskets

Simple design, baskets with large screening areas are tightly sealed one from the other. - Strong rear spray for complete washing

An original screen spray nozzle is set in parallel to wash out the entire basket by generating a strong spray pattern.

Dual Flow Type

- No debris carry over

Dual flow keeps debris outside without carry over to the downstream side because the screening area is sealed tightly from the other. - Larger screening area in a compact basket

Dual flow pattern doubles the effective screening are in a compact basket and allows to install narrower baskets without increasing flow velocity. - Submerged parts are simple and easy to maintain.

The underwater bearings for the foot sprocket are eliminated.

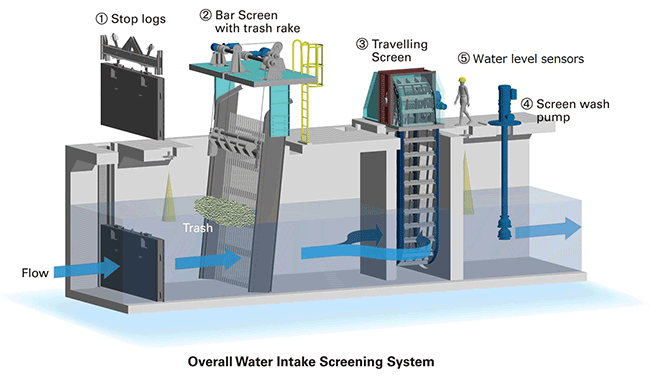

The overall water intake screening system

The overall water intake screening system consists of Stop logs, Bar screen with trash rake, Travelling screen, Screen wash pump, and Water level sensors.

Main Applications

Mitsubishi screen equipment are used on the water intake in the following places,

- Electricity power stations, petrochemical industries, oil refineries, steel works.

- LNG ( Liquefied Natural Gas ) terminals.

- Desalination plants.