- Water treatment

- Water treatment

De Hoxar Spiral Separator

- Water treatment

- Water treatment

De Hoxar Spiral Separator

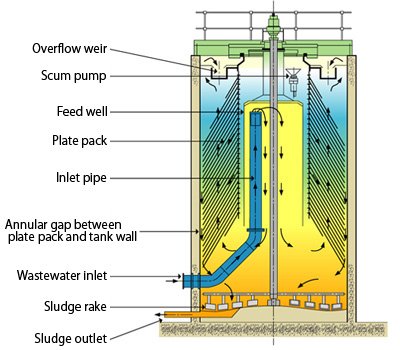

The De Hoxar Spiral Separator is a novel, compact gravity settlement device comprising a spiral plate pack within a tall circular settlement tank. The plate pack rotates continuously in conformity with rising speed of wastewater and capture settling particles on the plate efficiently. Having a small footprint and low operating costs, the separator is used in sewage treatment plants, water purification plants and industrial wastewater treatment plants to settle and thicken sludge.

This equipment technology( w095/01215 ) is introduced from Southern Water Services in England under the license agreement.

Features

- Spiral separator has a footprint about one tenth that of conventional settling tank.

- It allows collection of 2 - 3 times thicker sludge than that produced in conventional sedimentation tank.

- The rotating speed of the plate pack is matched to the upward flow rate of wastewater which is fed through the inlet pipe. This reduces turbulence on the plate and realizes superior separation performance of suspended particle and liquid over conventional sedimentation tank.

- The cost of construction, including installation and civil engineering work, is around a half of that for a conventional sedimentation tank.

Process Flow

Wastewater enters the separator via an inlet pipe to the feed well, then it flows downward once and goes up passing through plate pack. The plate pack separates the suspended particles and treated water is discharged into the overflow weir at the top of the tank. The plate pack is rotated at the adequate speed matching with the rising speed of wastewater passing through it. Thus the plate pack captures settling particles on the plate effectively in a higher speed than the conventional sedimentation process. The settled solids on the plate slides down easily toward the edge of each plate by its rotation and sank down through the annular space between the rotating plate pack and the tank wall onto the floor of the tank and is then discharged from the sludge outlet.

Lineups

| Model number | SST-1.5 | SST-2.5 | SST-3.5 | SST-5.0 | SST-7.0 | SST-10.0 |

|---|---|---|---|---|---|---|

| Tank diameter (m) | 1.5 | 2.5 | 3.5 | 5.0 | 7.0 | 10.0 |

| Tank Height (m) | 3.9 | 5.5 | 6.8 | 8.8 | 10.5 |

13.0 |

| Throughput (m3/day) | 410 | 1,700 | 3,700 | 11,000 | 23,000 | 62,000 |

| Surface loading (m3/m2/d) | 230 | 350 | 390 | 560 | 600 | 790 |

*The above throughput shows the capacity when the spiral separator is used in the primary settlement tank.

Main Applications

- Primary settlement tank.

- Final settlement tank.

- SS recovery from recycle flow

- Alternative to gravity thickening tank

- Combined sewage treatment

- Advanced treatment ( chemical precipitation tank )

- Potable water settlement tank

- Industrial wastewater settlement

- Construction site wastewater settlement

- Sand filtration

- Filter press washing waste water treatment

This product is for use only in Japan.